Roof truss roll forming machine for top hat purlin, light keel,

roof batten panel with embossing/ stiffener

General instruction:

A roll former that manufactures steel roofing and ceiling battens

(typically HAT shaped purlins) is known as roof batten roll forming

machine or ceiling batten roll forming machine.

Batten has multiple meanings in construction and shipbuilding but

is generally a strip of solid material, historically made from wood

but can also be made from plastic, metal, or fiberglass. In the

steel industry, battens used as furring may also be referred to as

“top hats“, in reference to the profile of the metal.

Quick Detail:

- Thickness : 0.4-0.6mm

- Material : GI, 550Mpa

- Input width : 100mm

- Material weight: 1.5MT cap.

- Driven way: by 4Kw driven motor

- Cutting way: stop to cut, there is waste after cut-off

- Cutting tolerance : ±1mm

Machine list:

- 1.5MT*300mm manual un-coiler

- Roll forming machine

- Hydraulic cutting device

- Run out table

- PLC control system

Description/Technical Parameter details of complete line:

- 1.5TX300mm Manual Un-Coiler

Un-powered; Load capacity= MAX.1.5Ton

Coil inner–diameter=410-570mm

Coil Width= MAX.300mm

- Roll forming machine with cutting details as below table :

| Suitable roll forming material | galvanized steel sheet |

| Thickness | 0.4mm-0.6mm |

| Coil input width | 100mm |

| Carriage Frame design | Wall-plate-frame-design |

| Rolling mills forming stages | 12 stages |

| Material of forming roller | 45# steel, CNC lathes, Hard Chrome Coated |

| Shafts Diameter | Φ65mm |

| Main motor power | 4Kw with reducer |

| Line speed of roll former | 15mtr per min |

| Hydraulic group power | 3.0 Kw |

| Material of cutting blade | Cr12, hear treatment |

| Electric Voltage Standard | 415V/50Hz/3PH or requirements |

| Major Color of Machine Painted | RAL 5015(Blue) or customized |

Siemens brand PLC and touch screen, Schneider/ Shihlin/ Delta brand

Inverter, Omron encoder

Cut-to-length tolerance≤±1mm

Control Voltage 24V

- Product Rack 4 meter length rolled type

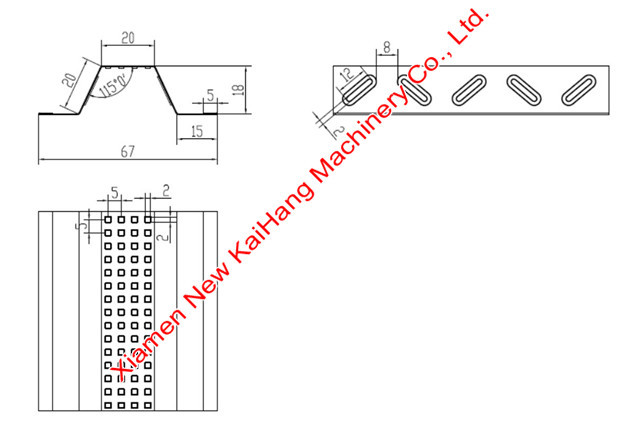

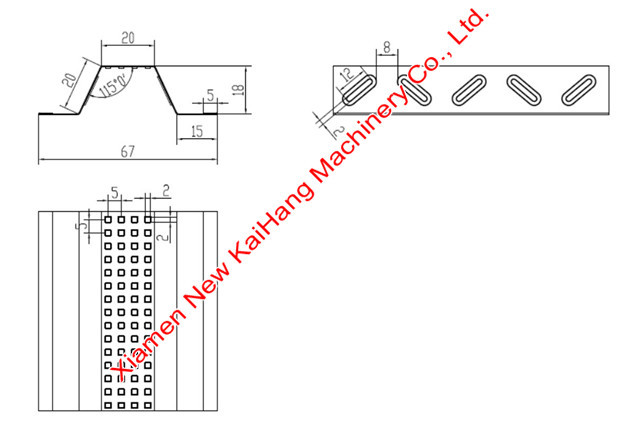

Profile Drawing/Layout/Equipment reference pictures: