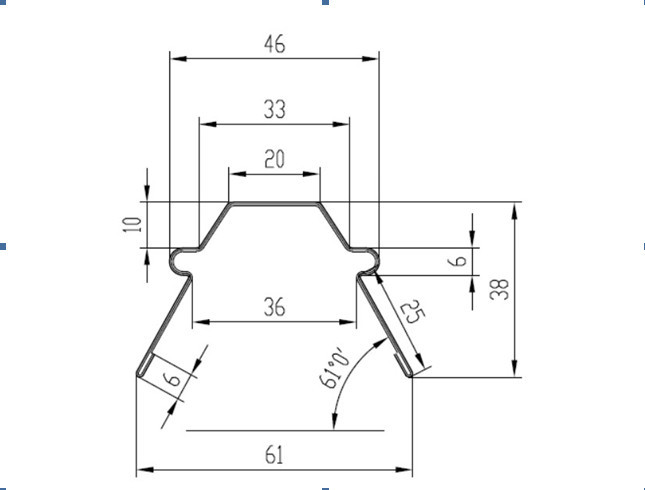

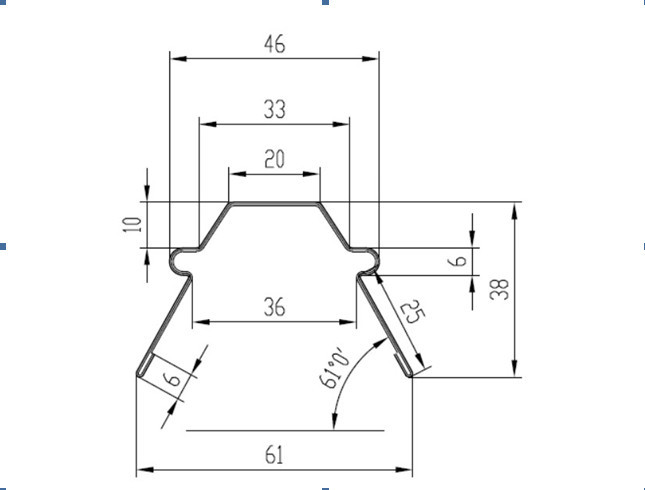

Top trim/ flashing roll former to cover the roofing panel, smart

design for small rolling machine

Quick Detail:

- Thickness : 0.42mm-0.6mm

- Material : Pre-painted Coil, 345Mpa

- Input width : 136mm

- Material weight : 1.5MT

- Cutting way: by hydraulic group, no waste cut

- Cutting tolerance : ±1mm

Description/Technical Parameter details of complete line:

- 5TX1250mm hydraulic de-coiler with/without coil car

Un-powered; Load capacity= Max.1.5Ton

Coil inner–diameter=410-570mm

Linked connected type design

Coil Width= Max.300mm

- Roll forming machine with cutting details as below table :

| Suitable roll forming material | Pre-painted Sheets, 245-550Mpa |

| Thickness range | 0.42mm-0.6mm |

| Coil width | 136mm |

| Carriage Frame design | Wall-plate-frame-design |

| Roll forming stages | 16 stages |

| Material of forming roller | 45# steel, CNC lathes, Hard Chrome Coated |

| Shafts Diameter | Φ65mm |

| Main motor power | 4Kw with reducer |

| Rolling speed of roll former | 18m/min |

| Hydraulic group power | 3.0 Kw |

| Material of cutting blade | Cr12, hear treatment as normal design |

| Electric Voltage Standard | 380V/50Hz/3Ph or as the customer's requirements |

| Major Color of Machine Painted | RAL 5015(Blue) or as per customer’s requirements |

Siemens brand PLC and touch screen, Schneider/ Shihlin/ Delta brand

Inverter, Omron encoder

Cut-to-length tolerance≤±1mm

Control Voltage 24V

- Product Rack Un-powered, 3 units

Machine list:

- Hydraulic un-coiler with/without coil cart

- Normal speed roll former

- Hydraulic cutting device

- Run out table or automatic stacking device for quick packing

- Siemens PLC and touch screen, Schneider brand inverter

Features:

A trapezoidal roof panel roll forming machine is always adjustable

for different feeding widths. You can make trapezoidal roof panels

with different effective widths from different-width materials.

This panel is to cover between two roofing panel pitches.

So this panel can be done by roll former or by pressing dies or by

folding machine also.

Profile Drawing/Layout/Equipment reference pictures: