Trim and flashing batten roofing machine, 2 in 1 design, cold

rolling mills, twin side, one driven motor

1. Twin side roll forming machine

Combined twin side building material machinery steel sheet roll

forming machine can handle the entire machine frame or parts,making

the rusty surface clean and smooth The surface of the product

increases adhesion. Combined double layer building material

machinery steel tile roofing sheet roll forming machine .

Combined twin side building material machinery steel sheet roll

forming machine make the backboard of stud and track machine, also

make the holes on backboard. This milling machine can milling the

backboard more level, hole place is more precious. This can make

the roller more level after installing,and then the purlin will be

more straigh

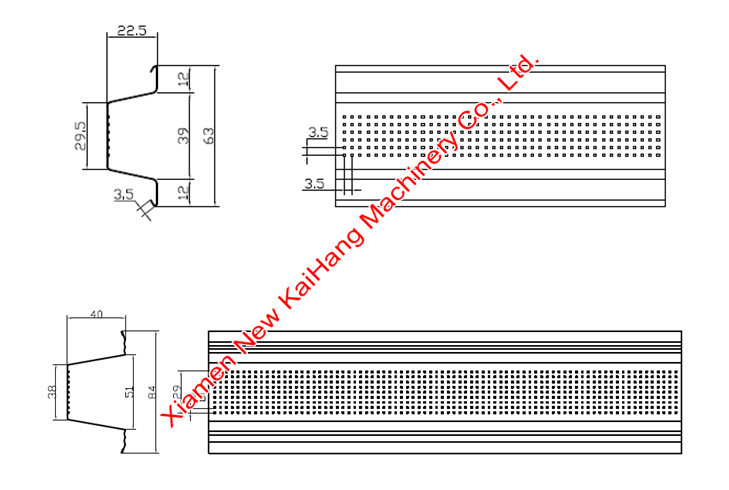

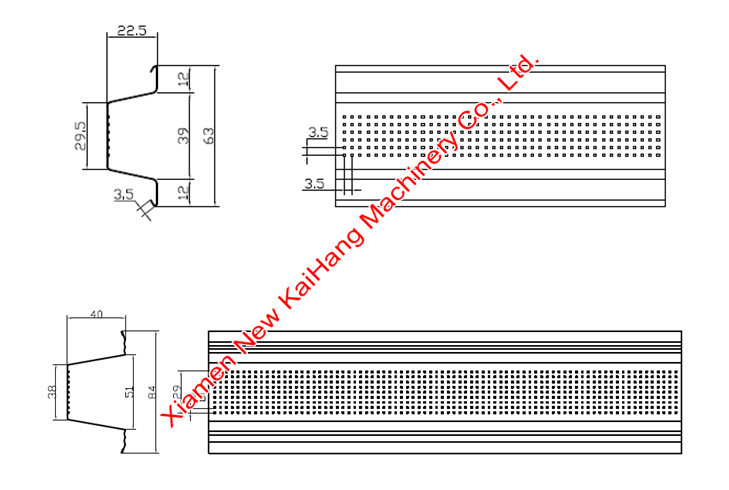

2. Technical details of double layer roll forming machine

Model | BATTEN |

Production speed | Max 25m/min |

Pressed shaft diameter | Φ65mm |

Profile wheel | 45# steel hard chrome plating |

Equipment chassis | PIPE |

Number of forming rows | 14/14 |

Platen thickness | 0.42-0.6mm |

Hydraulic shearing machine power | 5.5kw |

Voltage | 380V/220V |

Dimension | 5500*1400*1500mm |

Weight | 6500kgs |

3. Main components of twin side roll forming machine

MACHINE COMPONENTS FOR METAL ROOFING SHEETS PANEL ROLL FORMING MACHINE |

Name | Model/name | Quantity | Technical description |

| Hydraulic decoiler or Manual | | Capacity: Max. 3Ton,hydraulic control steel coil inner bore

expanding, shrinkage and stop. |

| Material Guiding System | 1 set | For feeding in a right position no Deviation. |

Precutting Device | 1 set | Pre-cutting or hydraulic cut |

Main Roll Forming Machine | 1 set | About 12/12 steps base on the design |

3.Cutting system | Hydraulic Cutting | | Precutting and postcutting both. |

4.Hydraulic system | Hydraulic Station | 1 set | Providing the power of cutting. |

| | | PLC control system, encoder positioning and cut-to-length

automatically, touch screen operating. |

6.Racking system | Exit rack | 3 PC | no power. |

4. Production Flows

Uncoiling the sheet---Infeed guiding--Roll forming---Rectifying the

straightness---Measure length---Cutting the panel--panels to the

supporter (option: automatic stacker)

5. Advantages

The advantage of roof sheet making double layer roll forming machine

1.The system is easy to operate and use. PLC: Siemens (Can

customize as customer require)

2.The surface of the final product is very beautiful without any

scratch on the surface.